//php echo do_shortcode(‘[responsivevoice_button voice=”US English Male” buttontext=”Listen to Post”]’) ?>

We are embarking on a path of transformational technological innovations that will have far-reaching consequences for both our everyday lives and for the good of the planet. Advances in the design and realization of kinetic energy harvesting generator (EHG) devices can now offer 20 to 30 times more energy compared with their predecessors. That added utility and functionality opens new doors for applications.

A single button press from an EHG can serve enough energy to read sensors, perform complex computations and transmit data using some of the latest, most complex and evolving communications protocols–all without the use of batteries and without ever needing servicing.

The IoT grew out of machine-to-machine (M2M) communications, which was typically direct, wireless communications from one powered machine to another or to a central data processor.

Low-power, wireless communications, extended life batteries and the highly connected internet resulted in the explosive growth of connected, mobile devices called the Internet of Things (IoT) and its industrial cousin, IIoT.

It also resulted in an explosive growth in battery consumption and waste disposal. Attempts to reduce battery consumption/extend life by minimizing ON time of the 10mW to 500mW radio (or other power-hungry hardware not needed 100% of the time) and minimizing the 1~10uW sleep power only delay the inevitable: battery replacement and disposal.

While this battery management strategy has enabled many new applications to become commonplace, other monitoring and activation applications found batteries unacceptable. The use of light and other power sources to supplement or replace battery power has been around since the calculators of the 1970’s and 1980’s. Small switches use kinetic energy harvesting to generate 100~500uJ of raw energy and deliver~10mW for ~20ms. This is enough for short-range alarms and controls, such as remote keyless entry. With hand-crafted firmware optimized for cold boot time, it is even sufficient energy for BLE beacons and similar protocols.

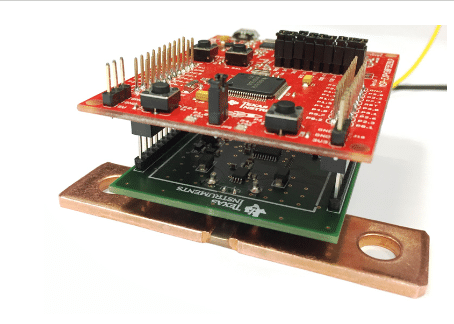

My partners at WePower Technologies and I demonstrated an advance in this technology at CES this year, delivering over 7000uJ of gross energy from a 22mm industrial pushbutton switch.

This demonstration netted 2500uJ of regulated 1.8V energy. The demo used full stack Zephyr RTOS with typical rapid application development tools and had sufficient energy to read sensors, 128-bit AES encrypt all sensor data, update ferroelectric RAM for non-volatile storage, and transmit numerous alert packets on BLE at 8-dBm.

All of that required a significant gulp of energy, and it came from the single button press of WePower’s battery-less EHG technology. And the technology was not just for show; WePower is ready for real-world deployment, actively seeking partnerships to bring our powerful solutions EHG to industries worldwide.

Wireless, industrial pushbuttons are highly desirable to overcome the high relative cost of running wires in conduit within an industrial plant, just as wireless switches and doorbells are so desirable for renovating and updating existing home construction with minimally invasive installations. These wireless switches and buttons become even more compelling when there is also no need to test and replace batteries.

The 2500uJ of regulated power is also potentially sufficient to send short messages over long distances using high-power (20-30dBm) BLE or using spread spectrum methods, such as LoRaWAN. Reliable, long-distance applications are compelling when batteries are eliminated because the cost to test and service batteries in remote locations is prohibitive.

The same kinetic generator was also demonstrated by WePower as a vibration-powered, continuous harvester by removing the switch mechanics and allowing the harvesting magnetics to move freely. Mounted on a speaker cone as a vibration source for test, the device harvested from ~1mW to ~50mW of continuous power. This is enough to power a vibration sensor, perform analysis and transmit continuous vibration data to a central asset-monitoring and predictive-maintenance system. These power levels are even suitable for more industrial protocols, such as WirelessHART.

Enabling a reliable, battery-less, and wireless industrial vibration monitor that would also be intrinsically safe (explosion-proof) has enormous applications in predictive maintenance of large pumps, motors and generators. Municipal water supplies, oil and natural gas pipelines and refineries, cargo port cranes and electric power generation are just a few applications for such sensors.

Monitoring vibrations would immediately alert people to sudden, unbalanced loads that could be dangerous. Analyzing the long-term trends of vibration would enable predictive maintenance.