What is Service Factor?

The service factor (SF) is a measure of the periodically overload capacity, or the amount of extra load a motor can handle for short periods without sustaining damage. The SF is usually expressed as a decimal or a percentage above the motor’s rated power or horsepower (HP). For example, if a motor is rated at 10 HP and has a service factor of 1.15, it can handle 11.5 HP for short periods without damage.

Related Article: 3-Phase AC Motors: Types, Design Characteristics and Common Use

The National Electrical Manufacturers Association (NEMA) sets standards for electrical equipment, including motors. The NEMA standard service factor for totally enclosed motors is 1.0, meaning that these motors are designed to operate at their rated nameplate horsepower and should not be overloaded beyond that point.

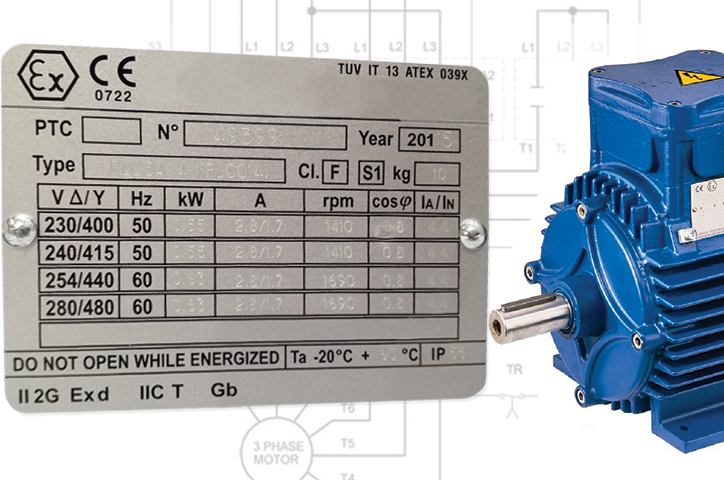

| Figure 1. NEMA Service Factor at Synchronous Speed (rpm) for drip proof motors |

When a motor is operated continuously at a service factor greater than 1, it will experience increased stress and heat generation, which can cause premature wear and failure of its components, such as bearings, windings, and insulation. Therefore, running a motor at a service factor greater than 1 can result in reduced life expectancy and increased maintenance and repair costs.

Example:

Design Power vs. Motor Power and Service Factor can be expressed as

PD = SF P (1)

where

PD = design power (hp, W)

SF =service factor

P = motor power (hp, W)

Example – Design Power vs. Service Factor

A 1 HP motor with a Service Factor – SF = 1.15 can operate at

PD = (1 hp) x 1.15 = 1.15 hp

However, it is important to note that even if a motor is designed to operate at a service factor greater than 1, it should only be operated at that level for short periods and not continuously. The manufacturer’s recommendations and guidelines should be followed to ensure the motor’s reliable and safe operation. Additionally, regular maintenance and inspections are essential to detect and address any issues before they lead to motor failure.

When a motor is operated at a service factor greater than 1, it can experience several negative effects. One of the primary effects is increased heat generation due to the increased current flowing through the motor’s windings. This heat can lead to thermal expansion of the motor’s components, causing them to warp or deform, which can result in increased friction and reduced efficiency. Additionally, the increased heat can cause insulation breakdown, which can lead to short circuits or ground faults.

Related Article: Principles of Electric Motor Protection

Another effect of operating a motor at a service factor greater than 1 is increased mechanical stress on the motor’s components, such as bearings and shafts. The increased stress can cause premature wear, leading to increased friction, vibration, and noise. The increased stress can also cause the motor to become unbalanced, which can result in additional wear and damage to the motor and the connected equipment.

~ End