The continual attraction of energy harvesting is well known. Who can resist possibly getting something—usually electricity—for nothing, or almost nothing? Yet the reality is that in many cases, the harvesting arrangement technically works but its cost in up-front hardware, longevity, actual harvested energy density, or other key metrics versus is an unbalanced, unfavorable situation.

But maybe that’s not a problem in a suitable application scenario. That’s what I found intriguing about a fuel cell developed by a Northwestern University-led team (which included three other universities) that harvests energy from microbes living in plain dirt, Figure 1.

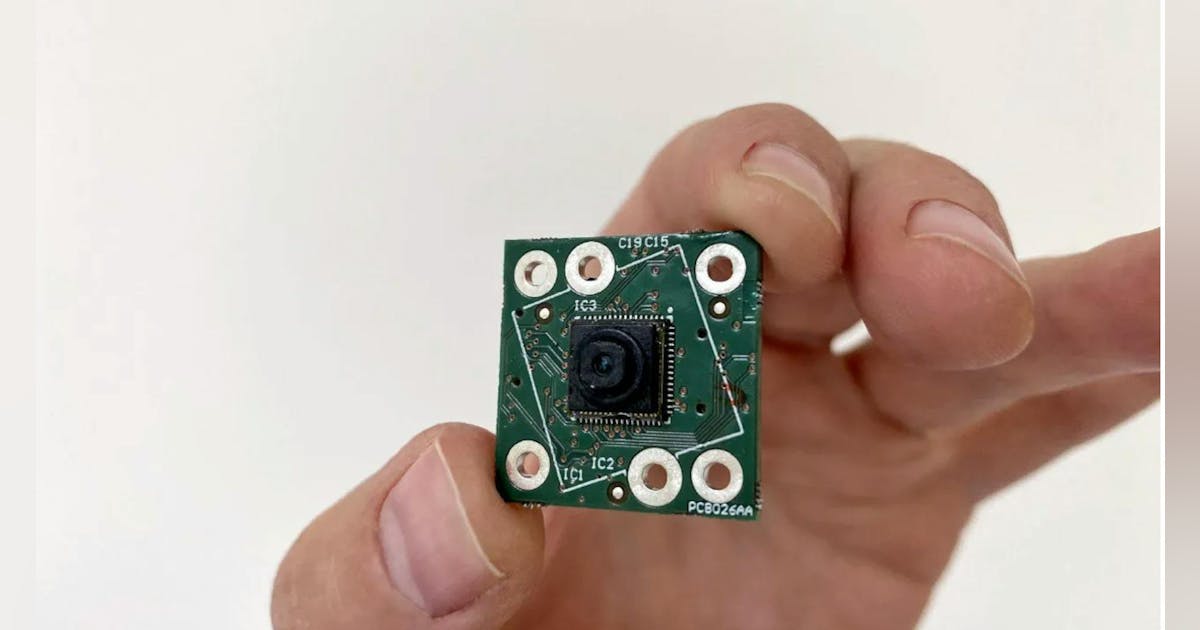

![]()

Figure 1 Working in the lab, Northwestern University project leader Bill Yen buries the fuel cell in soil. Source: Northwestern University

The team does not make the usual extremely optimistic claims made by proponents of some other harvesting approaches that their innovative technique is going to “save the planet”. Instead, said Northwestern’s George Wells, a senior author on the study, “These microbes are ubiquitous; they already live in soil everywhere. We can use very simple engineered systems to capture their electricity. We’re not going to power entire cities with this energy. But we can capture minute amounts of energy to fuel practical, low-power applications.”

Where is this scheme a good fit? It’s a natural fit for agricultural IoT situations, where it’s necessary to know soil conditions such as moisture levels and temperature. The obvious solution is solar panels, but they don’t work well in dirty environments because they get covered with dirt, do not work when the sun isn’t out, and take up a significant amount of surface space.

Another option is non-rechargeable batteries, but they have a limited lifetime. It’s not practical to expect farmers to go find these scattered sensor devices to replace that power source.

Use of soil-based microbial fuel cells (SMFCs) is not a new idea, as they have been around since the early 1900s. However, their inconsistent performance and low output power, especially in low-moisture conditions, has impeded attempts to deploy them widely. Nonetheless, as project leader Bill Yen noted, SMFCs offer a large potential advantage (no pun intended), since “As long as there is organic carbon in the soil for the microbes to break down, the fuel cell can potentially last forever.”

How they work

I won’t try to explain the microbiology details, as the research paper does so both briefly and also in detail with the required chemical equations, Figure 2. It says that “In a SMFC, the biofilm growing on the anode oxidizes organic matter to release electrons, which becomes the source of electrical power. The cathode performs a reduction reaction to balance out the cell’s net charge, which requires oxygen as a reactant. The electrolyte facilitates ion exchange between the anode and cathode while preventing oxygen from penetrating into the anode.” That’s a good-enough explanation for me.

![]()

Figure 2 The electrochemistry of the microbial-based fuel cell shows how it creates electron flow. Source: Northwestern University

The team set out to overcome the limitations of existing approaches. They designed and tested multiple prototype versions over several years and took the best for literal field tests. That version owes much of its success primary to a new geometry, rather than advanced materials

Instead of using a traditional design, in which the anode and cathode are parallel to each other, that fuel cell used a perpendicular design. It worked well in dry conditions as well as within a water-logged environment.

The anode is made of carbon felt while the cathode is made of an inert, conductive metal and sits vertically on top of the anode; the anode is in the horizontal position while the cathode is at right angles to it, Figure 3.

![]()

Figure 3 The physical construction and alignment of the cell’s components is critical to achieving its performance in challenging conditions. Source: Northwestern University

The top end of the anode is buried but flush with the ground’s surface. A 3D-printed cap rests on top of the device to prevent debris from falling inside, while a hole on top and an empty air chamber running alongside the cathode enable consistent airflow.

Since the lower end of the cathode is relatively deep beneath the surface, it stays hydrated from the moist, surrounding soil—even when the surface soil dries out in the sunlight. After any ground flooding, the vertical design enables the cathode to dry out gradually rather than all at once.

The results of their design were impressive but difficult to compare. The reasons are that there are different ways to assess performance, especially as the output is a function of many varying factors such as moisture level and its timing, temperature, soil type and texture, and more (note there are no defined IEC, ASTM or other standardized tests yet). This dilemma also makes it hard to compare the capabilities of this design to ones done elsewhere.

One of their many graphs does give some sense of the available output, Figure 4.

![]()

Figure 4 One of the may performance graphs shows the small but consistent power output achieved, but there are many varying factors to be considered. Source: Northwestern University

The power level of the cell dropped significantly after it was “transplanted” to the outside. However, it still produced enough power to theoretically turn on MARS during spikes in moisture levels caused by occasional irrigation; see shaded red regions for the energy which can be used by MARS. (Note: MARS is a nano-power battery-free wireless interface developed by other, unrelated researchers in 2021.)

They integrated their design with an RF-backscatter scheme to transmit sensor data in SMFC-powered system, Figure 5. Backscatter operates on the order of nanowatts, making them suitable for SMFC-powered applications. By using a purely analog backscatter device like MARS, they achieved superior performance in terms of runtime availability and robustness without using batteries and storage capacitors.

![]()

Figure 5 By combining the SFMC with an RF-backscatter scheme, they were able to build and test a complete sensor and data-reporting module. Source: Northwestern University

How much more improved is their design compared to other efforts? Short answer: it’s very hard to say, primarily due to lack of a standard test procedure as noted. However, they did report they felt the data showed it was an impressive ten to 50 times better.

Also impressive is their published paper, “Soil-Powered Computing: The Engineer’s Guide to Practical Soil Microbial Fuel Cell Design” (at the Proceedings of the Association for Computing Machinery on Interactive, Mobile, Wearable and Ubiquitous Technologies). At 40 pages, it is the longest academic-class paper I have ever seen, and for good reason.

How so? It is not just a report on what they did and the results. Instead, it’s really a complete design course. It discusses how they designed, built, and evaluated various versions until they reached their final one. It also explains how they identified the shortcomings of each version, and the flow-chart they devised for each observed problem as they methodically approached each, strived to identify one or more causes, and then minimized the problem. As a result, the paper is a comprehensive tutorial in the realities of a total project cycle, even if the result is not a commercially abatable device as is the case here.

What’s your view on the practicality of microbe and soil-based harvesting for these field applications? Have you even been attracted to energy-harvesting designs which appear to have significant capabilities, until you looked more closely at the realities of their implementation?

Bill Schweber is an EE who has written three textbooks, hundreds of technical articles, opinion columns, and product features.

Related Content