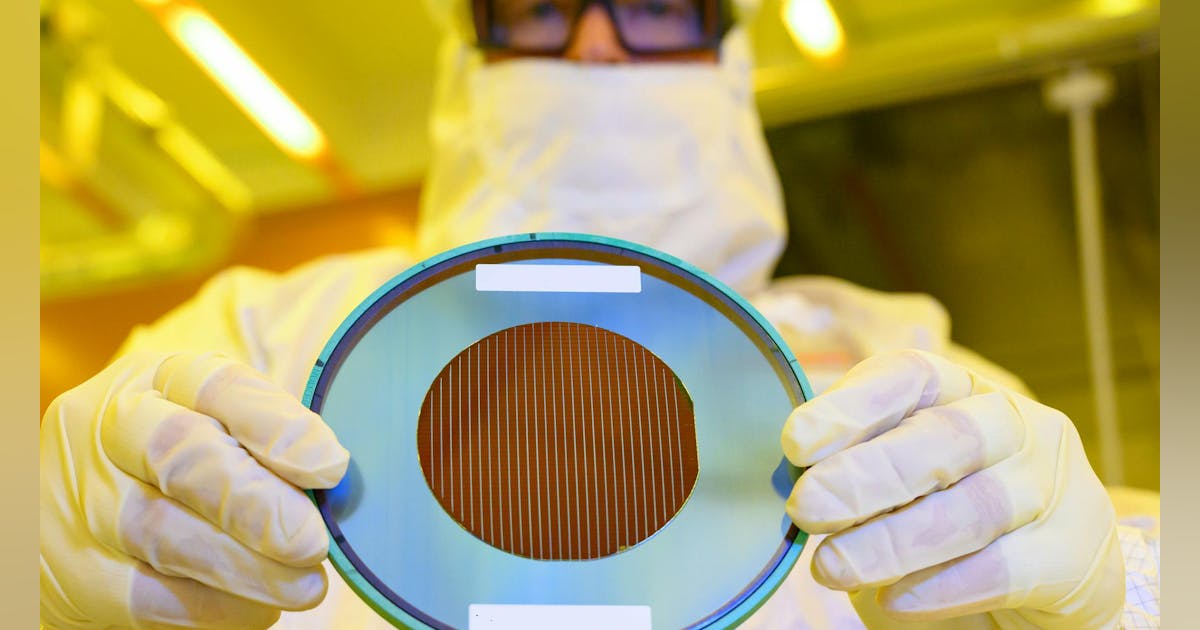

Uncontrolled vibration can cause semiconductor damage and decreased performance. Many sources of vibration challenge semiconductor manufacturers, including people’s footsteps, running machines, wind blowing in the building and passing vehicles. These sources can pose a significant challenge for design and manufacturing engineers.

Working in environments with poorly controlled vibrations can mean these professionals waste time and raw materials while designing and manufacturing new components or improving existing ones. What sources of vibration control should engineers consider?

- Facilities for vibration control

People involved with semiconductor manufacturing facilities under construction should be proactive and insist that those buildings have appropriate vibration controls. That was the approach of the design team associated with a $279 million project for a three-story semiconductor research lab.

The designers knew even tiny vibrations could negatively impact a semiconductor’s performance, potentially delaying or complicating research and manufacturing. Similarly, they recognized that the new facility must have contamination-mitigation features.

For instance, the building must have a clean room with a vibration-isolated floor. While working with those overseeing the construction details, the design professionals created a set of specifications adhering to their vibration-dampening and contamination-preventing needs.

Designers considering temporarily or permanently working at existing semiconductor facilities should ask which measures those buildings have, ensuring they reflect industry standards. That proactive measure helps designers work at places where they will spend their time well.

- Specialized products to interrupt and absorb vibration

Semiconductor manufacturing plants must have integrated products that absorb incoming vibrational energy and dampen external vibration sources. For example, a company may need to put thousands of spring mounts inside pipes and ductwork. However, the size and placement of the required spring mounts vary depending on the length and diameter of the building’s infrastructure.

It’s also often necessary to suspend pipes and ductwork from acoustic hangers after wrapping them in special housing. Some semiconductor facilities also have pipe connectors designed for specific types of vibration.

Those overseeing the construction or upgrading of a semiconductor fabrication facility should familiarize themselves with the off-the-shelf and custom-made products available to meet such needs. It’s also wise to get input from at least one consultant about how best to dampen the known or suspected types of vibration that will affect a fab.

- Install sensors to measure machine conditions

When electronics product designers consider the aspects of new items, they must think about whether such components could be manufactured on a facility’s existing equipment. Another thing to verify is whether the fab’s infrastructure has sensors to detect abnormal vibrations.

Due to the semiconductor industry’s heavy dependence on water during manufacturing, a pump failure could be an extremely costly and disruptive problem. Rotor pumps spin as fast as 30,000 rotations per minute and vibrate more when rotor damage occurs. This issue generally requires a total pump replacement.

Advanced sensors can measure tiny changes—such as progressively increasing vibration—and warn technicians that failures will happen soon. Such information allows fab professionals to order new parts or schedule service calls before outages occur. Decision makers could also use these sensors as vibration monitoring tools and act quickly to mitigate new issues.

Vibration control is essential

Poor or non-existent vibration-control measures in a semiconductor plant affect manufacturers and design team members. The above mentioned strategic measures can reduce or eliminate problems, helping everyone stay productive and get the best results from their work.

Ellie Gabel is a freelance writer as well as an associate editor at Revolutionized.

Related Content